A few weeks ago I was lucky enough to be able to look around the John Smedley knitwear factory. I left Lukas with Nanny and took Tomas with me on the tour all the way to the beautiful Peak District. It felt like my fashion years are back again!!

A few weeks ago I was lucky enough to be able to look around the John Smedley knitwear factory. I left Lukas with Nanny and took Tomas with me on the tour all the way to the beautiful Peak District. It felt like my fashion years are back again!! For those who don’t know John Smedley knitwear I really recommend to visit their website where you will find more detailed info (the whole history if you want). John Smedley is a family business that is owned by many generations of the same family. They still handcraft finish their garments and still maintain many traditional craftsmanship methods. So buying their knitwear is really worth the money if you want to add some staple jumpers and cardigans to your wardrobe as they are made to last ;-).

For those who don’t know John Smedley knitwear I really recommend to visit their website where you will find more detailed info (the whole history if you want). John Smedley is a family business that is owned by many generations of the same family. They still handcraft finish their garments and still maintain many traditional craftsmanship methods. So buying their knitwear is really worth the money if you want to add some staple jumpers and cardigans to your wardrobe as they are made to last ;-).

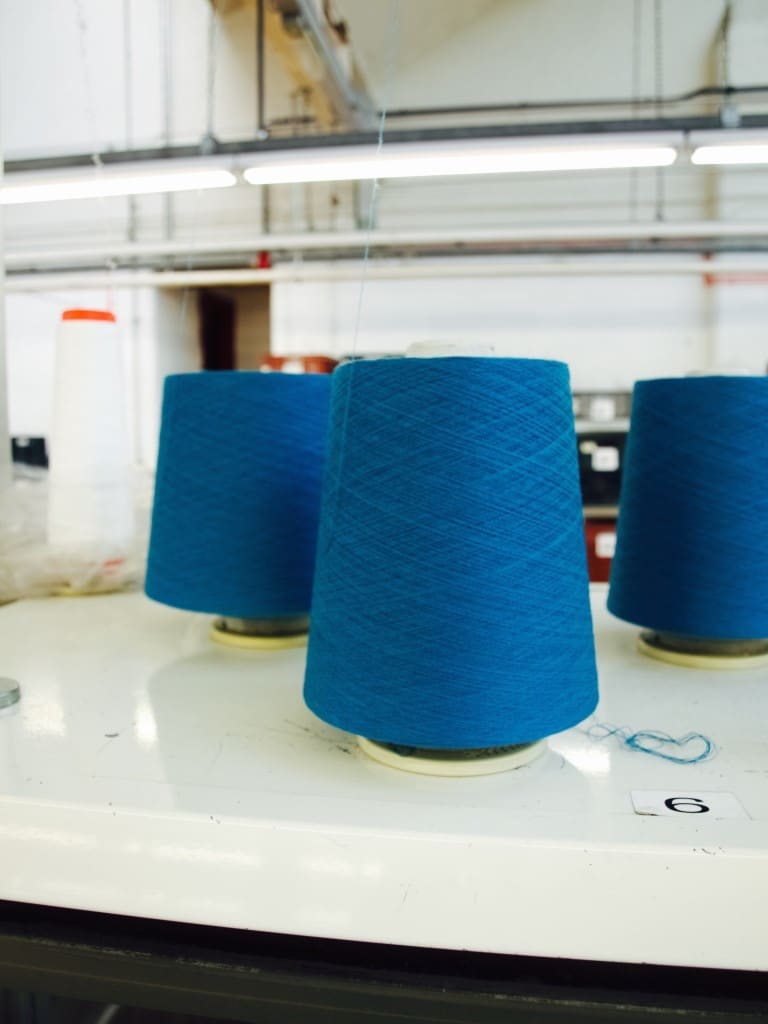

John Smedley knitwear starts with a good quality yarn, mostly made with sheep hair (or cotton for summer) which I was quite surprised by. My memories of sheep wool is not great and I remember it being rough and stingy on the skin. But wait, this yarn comes from special sheep that come from New Zealand (called merino sheep). Their hair is softer because of better weather conditions.

John Smedley knitwear starts with a good quality yarn, mostly made with sheep hair (or cotton for summer) which I was quite surprised by. My memories of sheep wool is not great and I remember it being rough and stingy on the skin. But wait, this yarn comes from special sheep that come from New Zealand (called merino sheep). Their hair is softer because of better weather conditions.  The yarn then gets washed and conditioned to achieve maximum softness.

The yarn then gets washed and conditioned to achieve maximum softness. As I was visiting John Smedley factory it was obvious that the quality is the top priority here. The knitting is checked and checked again at many different stages and gets rejected when it does not meet these high standards. But it does not go to waste. These clever machines unravel the knitwear so this beautiful yarn have another chance to become a piece of knitwear again. Pfew! Thats good to know ;-).

As I was visiting John Smedley factory it was obvious that the quality is the top priority here. The knitting is checked and checked again at many different stages and gets rejected when it does not meet these high standards. But it does not go to waste. These clever machines unravel the knitwear so this beautiful yarn have another chance to become a piece of knitwear again. Pfew! Thats good to know ;-).

I especially loved some of the older machinery that although it is vintage is still very well maintained and making quality garments(however these are a little louder than modern ones).

I especially loved some of the older machinery that although it is vintage is still very well maintained and making quality garments(however these are a little louder than modern ones).

Every piece of knitwear is kept on needles as you would expect (If you are knitter yourself you would understand what I mean here). There is special compartment for trims as you can see here that get later attached to the main body.

Every piece of knitwear is kept on needles as you would expect (If you are knitter yourself you would understand what I mean here). There is special compartment for trims as you can see here that get later attached to the main body.

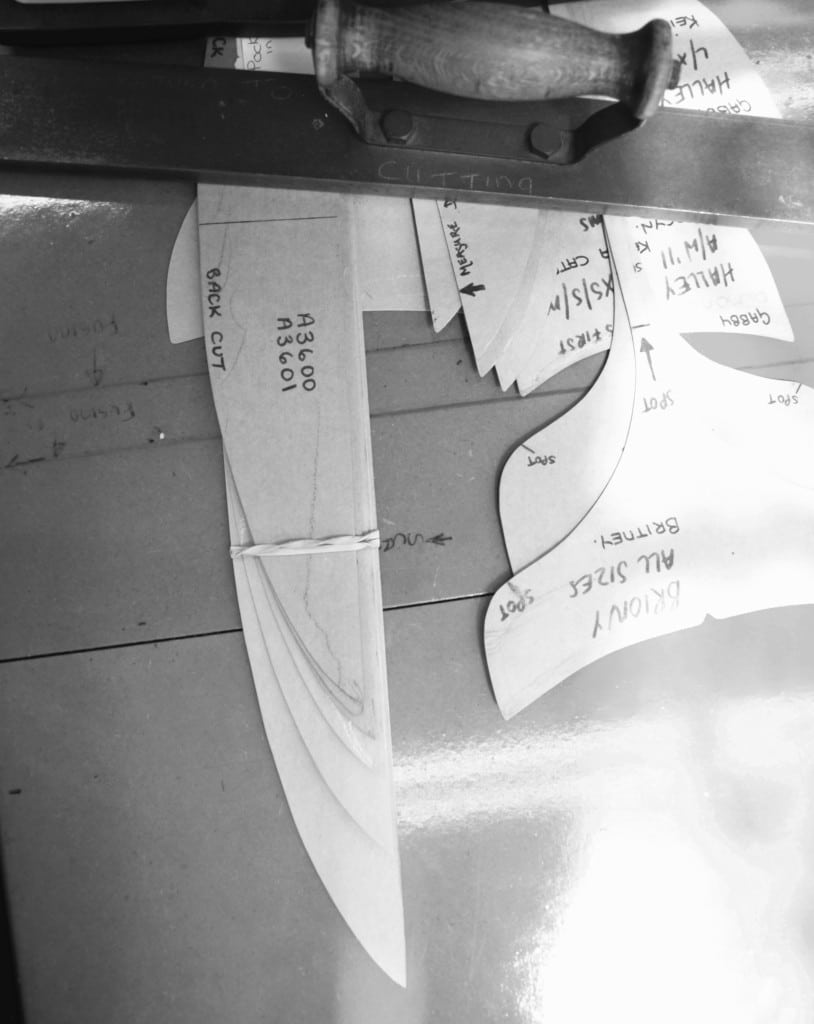

This is where the garment gets its handcraft finish. The neck hole is cut by hand and then a special machine knit stitches the body and the trim together.

This is where the garment gets its handcraft finish. The neck hole is cut by hand and then a special machine knit stitches the body and the trim together.

Finally each garment gets a final steam press.

Finally each garment gets a final steam press. The factory building has it’s old charms as well. The original water mill is still here, although it is no longer used to power the machinery it still makes a very pretty feature.

The factory building has it’s old charms as well. The original water mill is still here, although it is no longer used to power the machinery it still makes a very pretty feature.

Hope you found this post interesting as much as I did when visiting this fine knitwear factory ;-).

Hope you found this post interesting as much as I did when visiting this fine knitwear factory ;-).

Rasa xoxo

No comments yet.